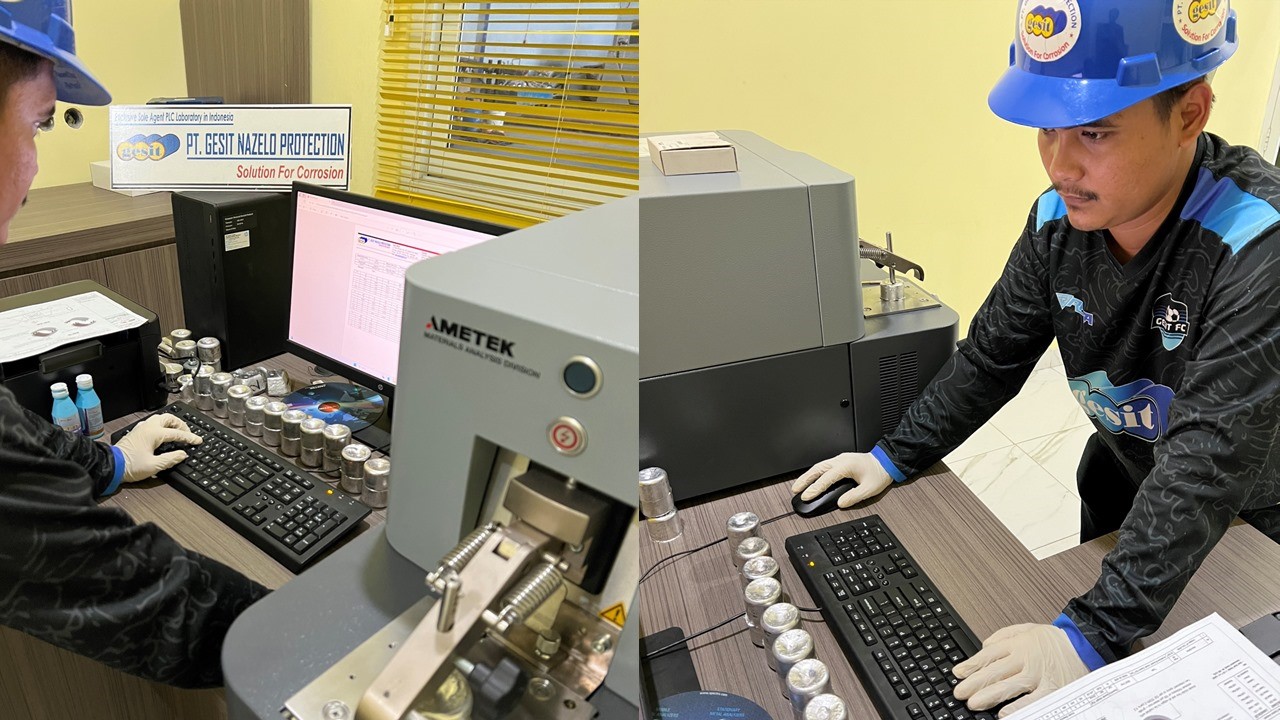

Manufactured using high purity Zinc and compliant with DNV, ISO, BKI, ASTM B418 Type I & II standards or customable as per project specification.

GESIT Zinc Anodes deliver consistent, reliable cathodic protection (CP) performance in marine and select onshore applications. Produced using premium-grade Zinc alloys, strict composition control, and advanced manufacturing processes, our anodes ensure predictable electrochemical characteristics and long service life. Zinc Anodes are trusted by shipbuilders, shipowners, offshore contractors, and industrial operators where regulatory, safety, and technical requirements specifically call for Zinc over other anode types.

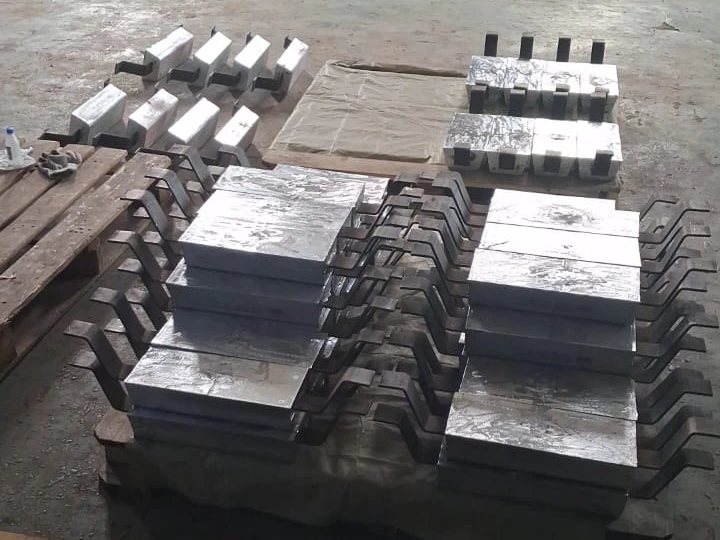

While GESIT can supply Zinc Anodes in almost any form—bracelet, long slender, flush mounted, ship anode, and even pre-packaged zinc for soil applications—practical and economic considerations typically make Zinc Anodes the choice for specific environments only. Zinc’s higher material cost and density means it is generally less economic than aluminium in seawater and brackish water applications. The application of pre-packaged zinc anodes is limited to select cases in onshore (soil) environments characterized by low resistivity.

Therefore, Zinc Anodes are predominantly selected when Aluminium Anodes are restricted or not recommended—such as on structures where there is a risk of spark/thermite reaction and compliance with safety and class society regulations is required.

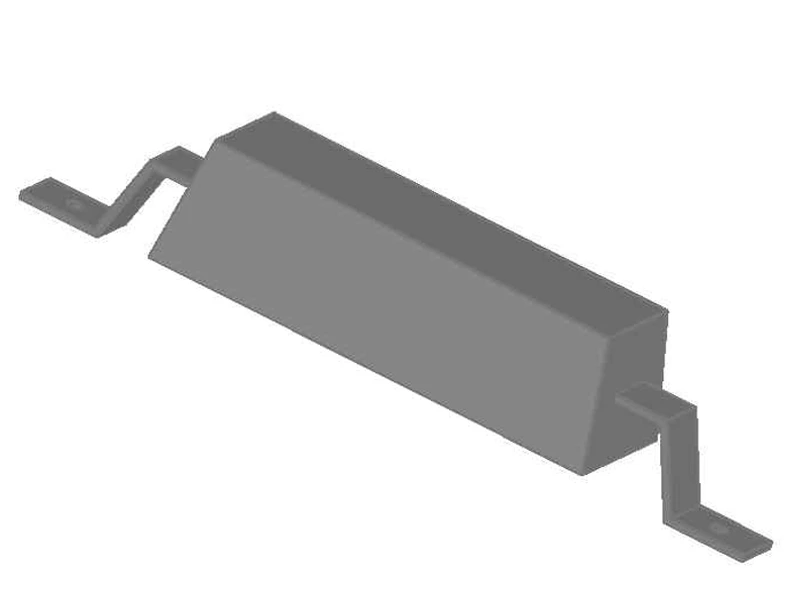

In such cases, Zinc Anodes are commonly supplied in flush-mounted and ship anode forms.

In seawater and brackish environments, the commonly used sacrificial anodes are Aluminium Anodes and Zinc Anodes. The key characteristics of Zinc Anodes are:

GESIT can supply Zinc Anodes with the following alloy and performance options:

GESIT provides comprehensive engineering and technical assistance:

GESIT Zinc Ship Anodes are designed for reliable sacrificial cathodic protection of marine vessels—both external (hull, rudder, propeller area) and internal (water ballast tanks, seawater tanks).

Manufactured from high-purity zinc alloys in accordance with ASTM B418 (Type I & Type II) and BS EN 12496, and compatible with DNV, ISO, NACE/AMPP, and BKI requirements, they provide stable and predictable protection in seawater and brackish environments.

Zinc ship anodes are widely used on commercial ships, offshore support vessels, workboats, and naval ships due to their well-understood electrochemical behavior and robust performance in marine service.

Typical applications include welded or bolted anodes on the hull, rudder, bilge keels, sea chests, thruster tunnels, and internal seawater/ballast tanks where class rules or safety considerations favor zinc over aluminium.

With appropriate alloy selection and placement, zinc anodes provide continuous protection over the vessel’s docking interval and can be easily inspected and replaced during drydocking.

External: ship hull, rudder, skeg, bilge keel, stern tube area, propeller brackets, thruster tunnels, bow/stern thrusters.

Internal: water ballast tanks, seawater service tanks, sea chests, pump rooms and other compartments with submerged steel surfaces and seawater exposure.

Offshore and support units: barges, workboats, tugs, and floating structures where marine immersion is continuous.

WhatsApp us