Magnesium anodes for soil and freshwater cathodic protection, manufactured in accordance with ASTM B843. These anodes provide reliable driving potential and consistent electrochemical performance for buried and freshwater-exposed steel structures.

Very high driving potential compared to Zinc or Aluminium Anodes:

Electrochemical capacity: typically ≈ 1,100–1,250 Ah/kg (depending on alloy and manufacturing).

Ideal for: structures in freshwater, buried pipelines, underground tanks and high-resistivity soils.

Not recommended for: seawater and brackish environments (excessive driving potential leads to rapid consumption / risk of over-protection).

Supply options: bare anode, pre-packaged with backfill, ribbon format, or custom bracelet/block/slender shapes.

GESIT supplies both alloy types across all product categories:

1. High-Potential Magnesium Anode (HP)

2. Standard-Potential Magnesium Anode (SP)

| Property | High Potential (M1C) | Standard Potential (AZ63B) |

|---|---|---|

| Open Circuit Potential | –1.70 to –1.75 V (Cu/CuSO₄) | –1.50 to –1.55 V (Cu/CuSO₄) |

| Closed Circuit Potential | –1.58 to –1.62 V (Cu/CuSO₄) | –1.45 to –1.50 V (Cu/CuSO₄) |

| Electrochemical Capacity | 1,100 Ah/kg | 1,200–1,230 Ah/kg |

| Current Efficiency | 50% minimum | 55% minimum |

| Ideal Applications | High-resistivity soils (>2,000 Ω·cm) | Medium-resistivity soils (<20 Ω·cm) |

High Potential Alloy (ASTM B843–M1C)

| Element | Content |

|---|---|

| Aluminum (Al) | 0.01% max |

| Manganese (Mn) | 0.50–1.30% |

| Copper (Cu) | 0.02% max |

| Silicon (Si) | 0.05% max |

| Iron (Fe) | 0.03% max |

| Nickel (Ni) | 0.001% max |

| Zinc (Zn) | — |

| Single Impurity (each) | 0.05% max |

| Total Impurities | 0.30% max |

| Magnesium (Mg) | Remainder |

Standard Potential Alloy (ASTM B843–AZ63B)

| Element | Content |

|---|---|

| Aluminum (Al) | 5.30–6.70% |

| Manganese (Mn) | 0.15–0.70% |

| Zinc (Zn) | 2.50–3.50% |

| Copper (Cu) | 0.02% max |

| Silicon (Si) | 0.10% max |

| Iron (Fe) | 0.003% max |

| Nickel (Ni) | 0.002% max |

| Single Impurity (each) | 0.05% max |

| Total Impurities | 0.30% max |

| Magnesium (Mg) | Remainder |

Bare magnesium anode encased in engineered backfill (gypsum–bentonite–sodium sulfate) to reduce soil resistance and stabilize consumption.

Available in: High Potential (HP) or Standard (SP) magnesium alloy.

Typical Net Weight:

3 lb (1,4 kg), 5 lb (2,3 kg), 9 lb (4,1 kg), 17 lb (7,7 kg), 20 lb (9,1 kg), 32 lb (14,5 kg), 40 lb (18,1 kg), 48 lb (21,8 kg), dan 60 lb (27,2 kg).

Cable Option:

GESIT provides a wide range of cable tail configurations for pre-packaged magnesium anodes, available in various insulation and armored or non-armored types such as XLPE/PVC, XLPE/AWA/PVC, XLPE/SWA/PVC, and HMWPE. Cable tails can be supplied in multiple AWG or metric sizes, customized according to project requirements and installation conditions.

Magnesium Long Slender Anodes (MLSA) are manufactured in accordance with ASTM B843 and designed for extended-length installation in freshwater. MLSA can be produced in two configurations:

Cast magnesium alloy in a trapezoidal long-slender shape, or

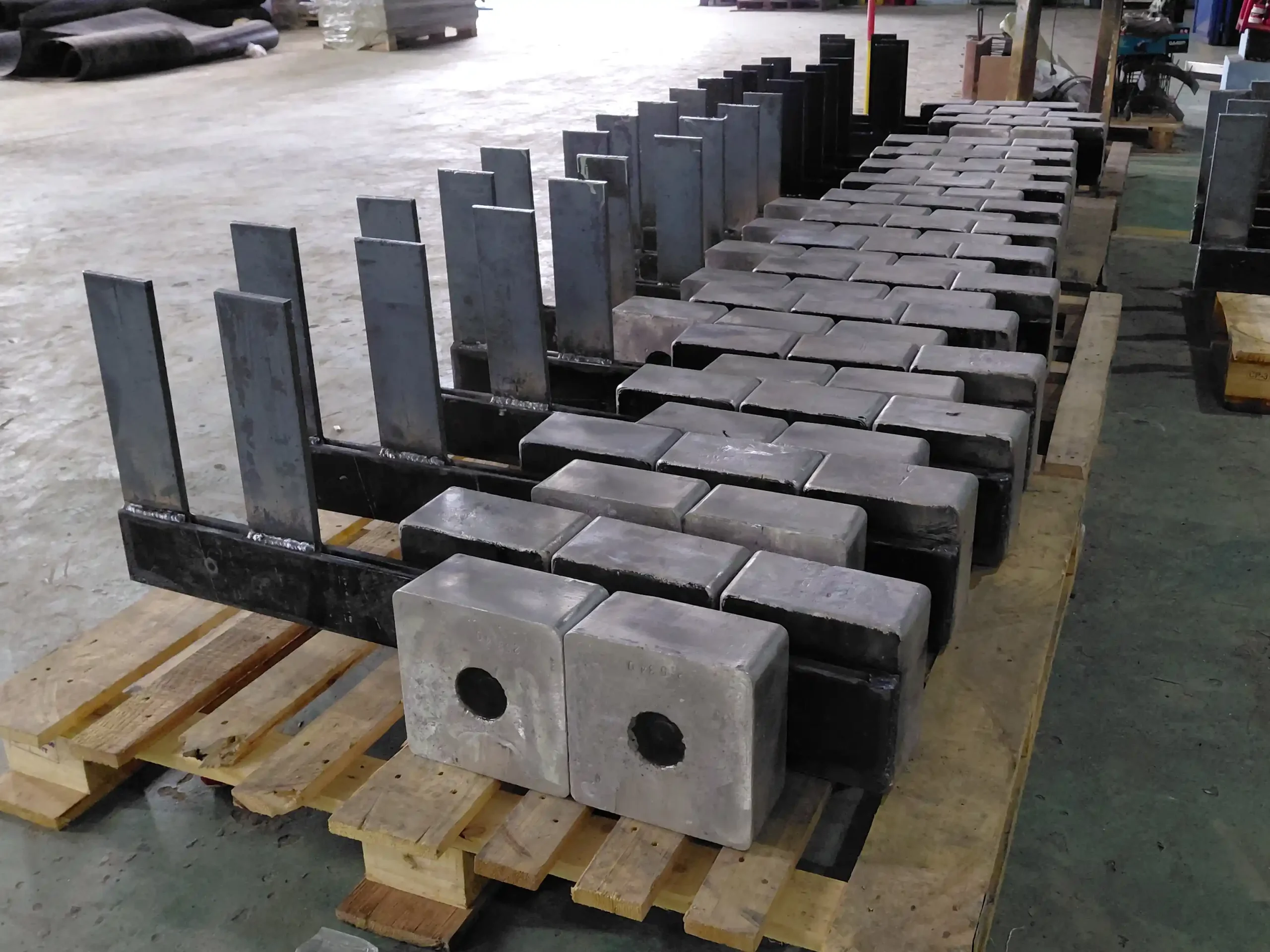

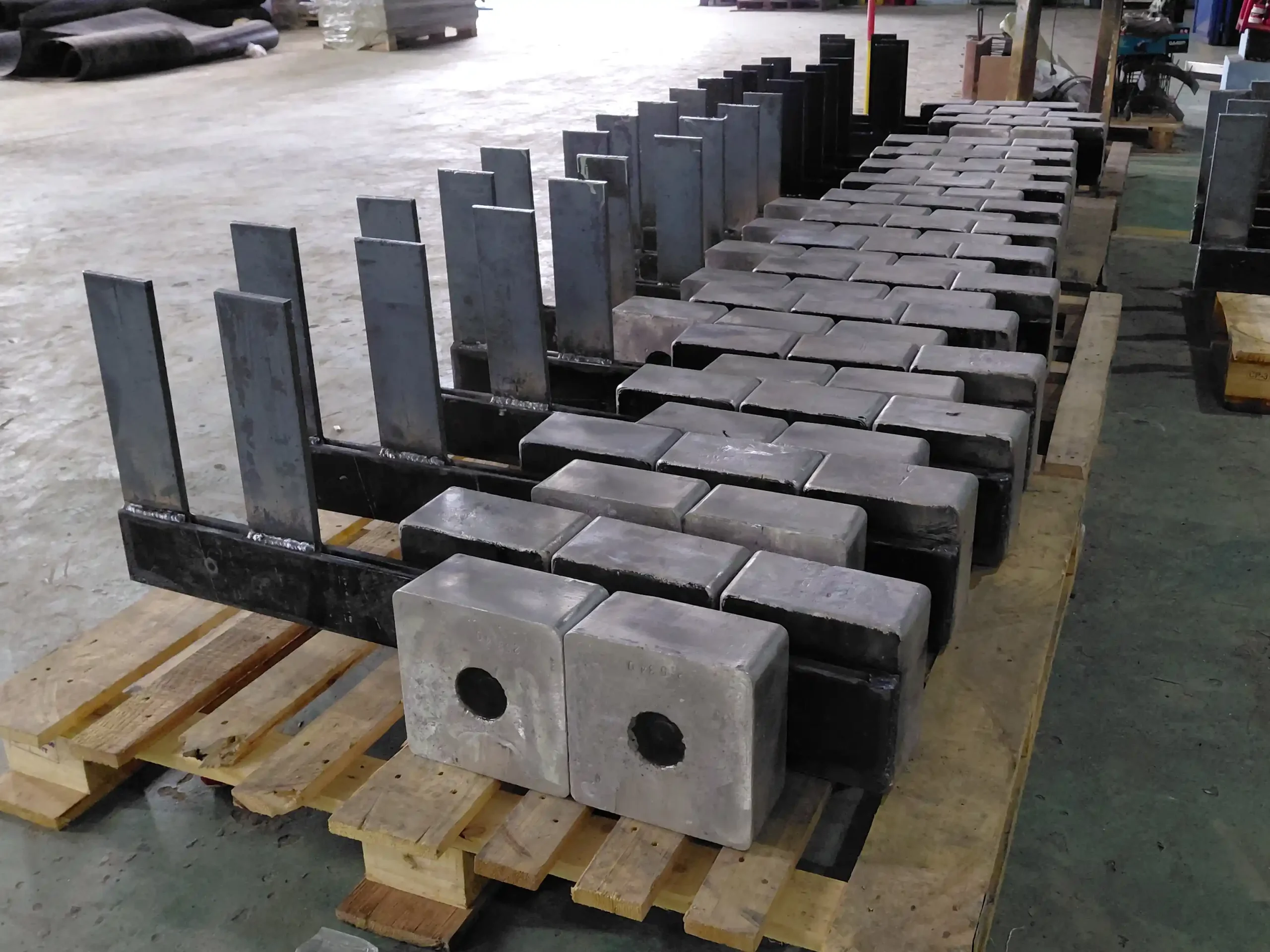

Magnesium condenser blocks assembled using engineered brackets to form a continuous long-slender anode.

Both manufacturing methods allow flexibility in geometry, length, and core/mounting configuration, and are available in either High Potential (HP) or Standard Potential (SP) magnesium alloys.

MLSA is used for structures in freshwater environments such as:

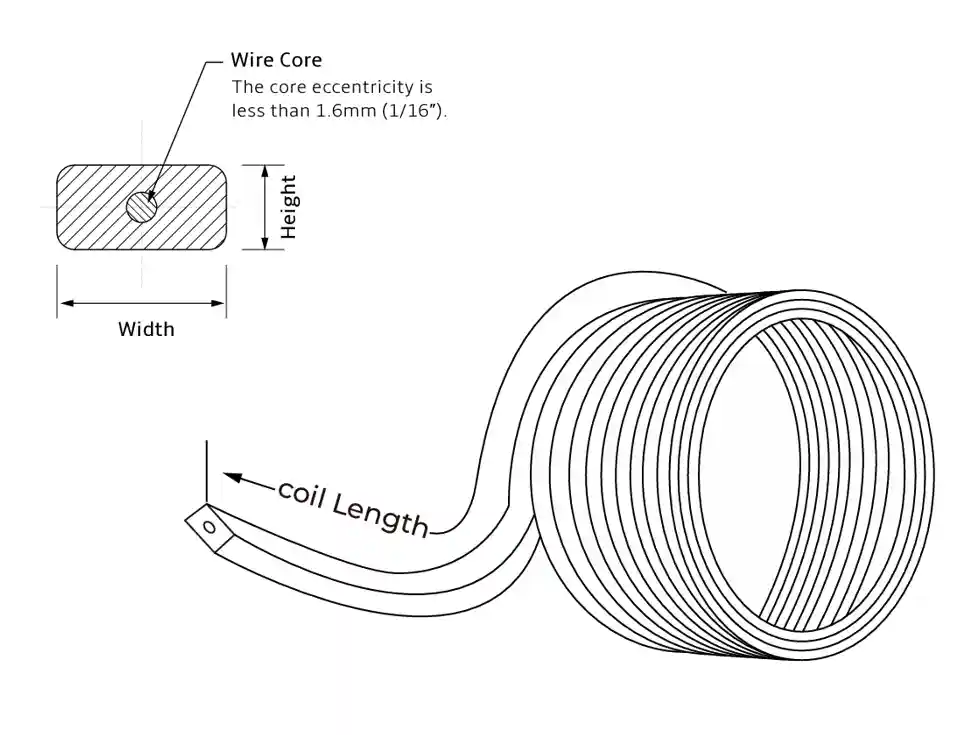

Magnesium Ribbon Anode is an extruded magnesium ribbon with a continuous galvanized steel core, manufactured strictly to ASTM B843 M1C alloy requirements. Its high driving potential (≈ –1.70 to –1.75 V vs SCE) and large surface-area-to-weight ratio provide efficient and uniform current distribution over long distances.

WhatsApp us