GESIT is committed to delivering guaranteed product quality that meets project specifications, on-time delivery, and competitive pricing.

As an integrated manufacturer and fabricator of sacrificial anodes, impress currect cathodic protection (ICCP) materials for onshore and offshore cathodic protection and coating systems, GESIT offers a full in-house production capability supported by strict quality control, complete traceability, and compliance with international standards.

To fulfill thecommitments, GESIT focuses on five core pillars:

Optimized manufacturing and inventory systems ensure consistent quality, minimal waste, and shorter lead times for reliable on-time delivery. Efficient resource usage also helps keep pricing competitive.

Skilled engineers and production teams maintain product quality, improve workflow efficiency, and reduce operational costs—supporting timely delivery and competitive pricing.

Reliable and well-maintained melting, fabrication, and handling equipment guarantee stable production output. Minimizing downtime allows uninterrupted manufacturing and cost efficiency.

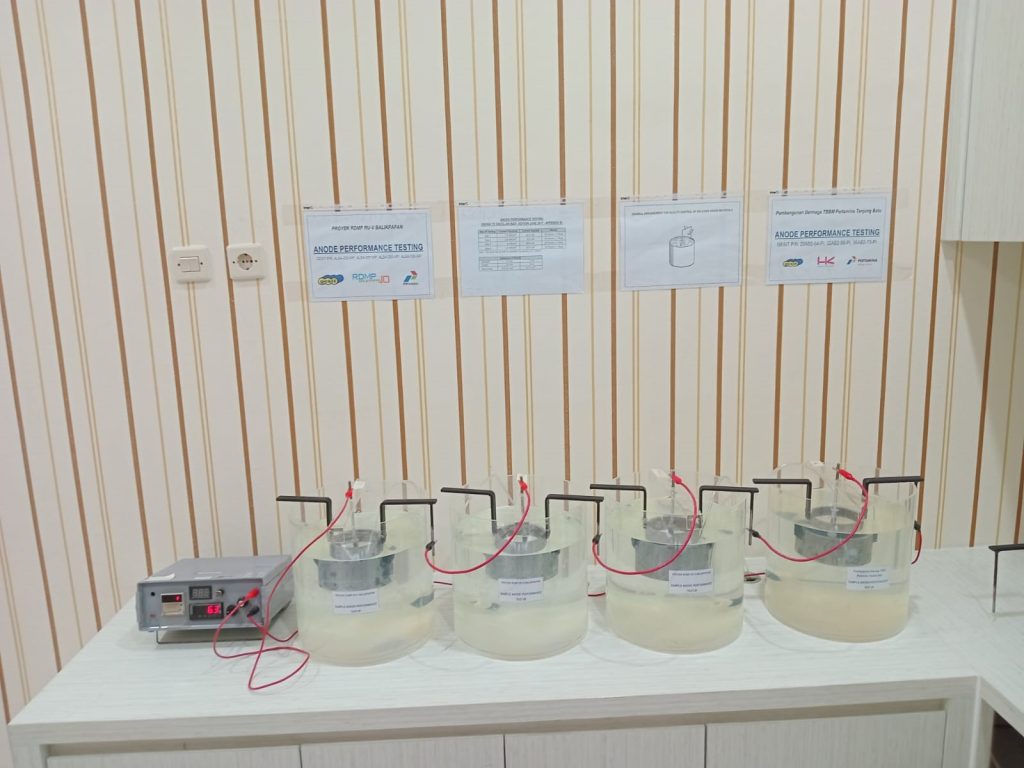

Regularly calibrated instruments enable accurate chemical, electrochemical, and dimensional testing. Rigorous QC ensures compliance with specifications, early issue detection, and smooth delivery schedules.

GESIT applies strict Health, Safety, and Environment standards across all operations. The use of electric furnaces and controlled processes reduces environmental impact while supporting a safe and efficient workplace.

GESIT’s manufacturing facility is located in Citeureup, Bogor (Greater Jakarta) and covers an area of approximately 3,200 m².

The plant combines engineering, QC, fabrication, warehousing, and operational offices in one integrated workflow. This setup ensures smooth coordination between departments and fast response to production requirements.

The following facilities support high-volume production, custom casting processes, and trial-fit activities for aluminum and zinc anodes, along with complete fabrication capabilities for magnesium anodes, ICCP anodes, and HDPE jacket piles.

Overhead crane, forklifts, preheat ovens, rolling and bending machines, cutting and drilling stations, welding workstations, blasting room, and dedicated finishing areas.

Electrochemical Testing using:

Chemical Composition Testing Performed using AMETEK SPECTROMAXx LMF-08 spectrometer to verify alloy chemistry for every production heat.

All standards related to cathodic protection & coating systems including but not limited to:

Manufacturing and inspection follow approved project documents including MPS, ITP, technical datasheets, and client drawings.

With complete in-house capabilities, strict quality control, and documented compliance, GESIT is a reliable partner for cathodic protection products across marine, offshore, pipeline, and industrial sectors.

WhatsApp us