Manufactured using high purity INALUM aluminium and compliant with DNV, ISO, BKI, NACE/AMPP standards or customable as per project specification.

GESIT Aluminium Anodes are engineered for long-lasting (as per design life), high-efficiency cathodic protection (CP) in seawater and brackish water environments. Manufactured with high-purity aluminium and compliant with international standards (DNV, ISO, BS EN, NACE/AMPP or BKI), our anodes are trusted by offshore operators, marine contractors, shipping companies, EPC companies, and shipyards across various industries.

If your project requires reliable corrosion protection for offshore platforms, pipelines, jetty structures, or marine vessels, GESIT provides complete aluminium anode solutions—customizable to any specification.

In seawater and brackish environments, the commonly used sacrificial anodes are Aluminium Anodes and Zinc Anodes. The key characteristics of Aluminium Anodes are:

Aluminium Anodes are used for corrosion protection in:

GESIT can supply Aluminium Anodes with the following alloy and performance options:

GESIT provides comprehensive engineering and technical assistance:

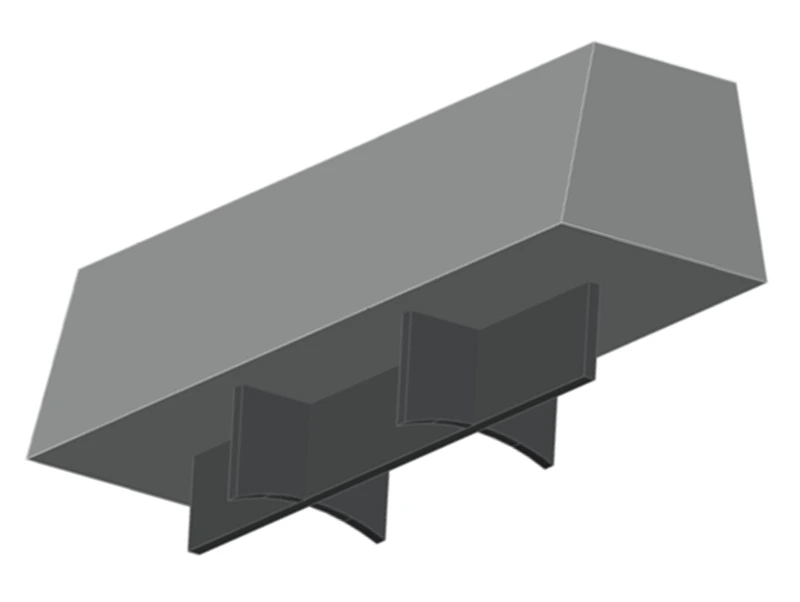

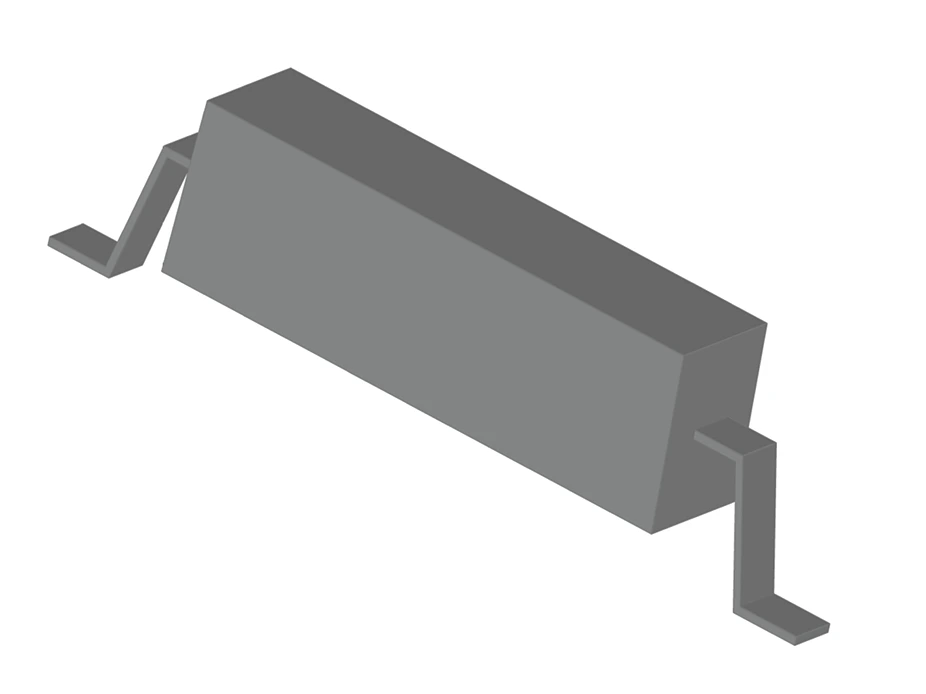

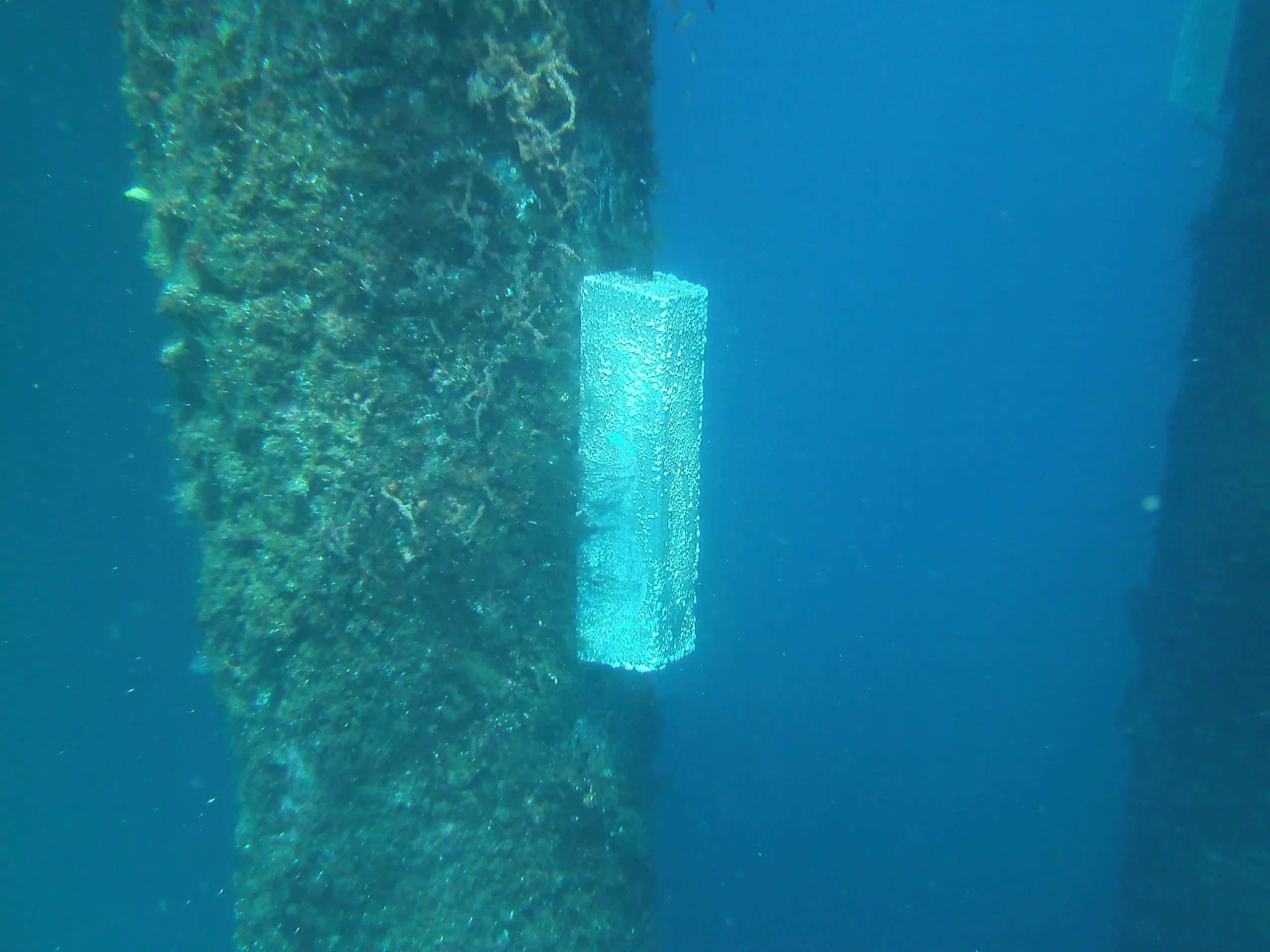

Designed specifically for cylindrical structures such as subsea pipelines and jetty piles, Aluminium Bracelet Anodes ensure uniform current distribution and long stable service as per design life.

The anodes are fully customizable in weight, dimensions, and alloy (chemical composition & electrochemical performance) according to design calculations or project specifications provided by the client.

For Submarine Pipelines:

For Jetty/Steel Pipe Piles:

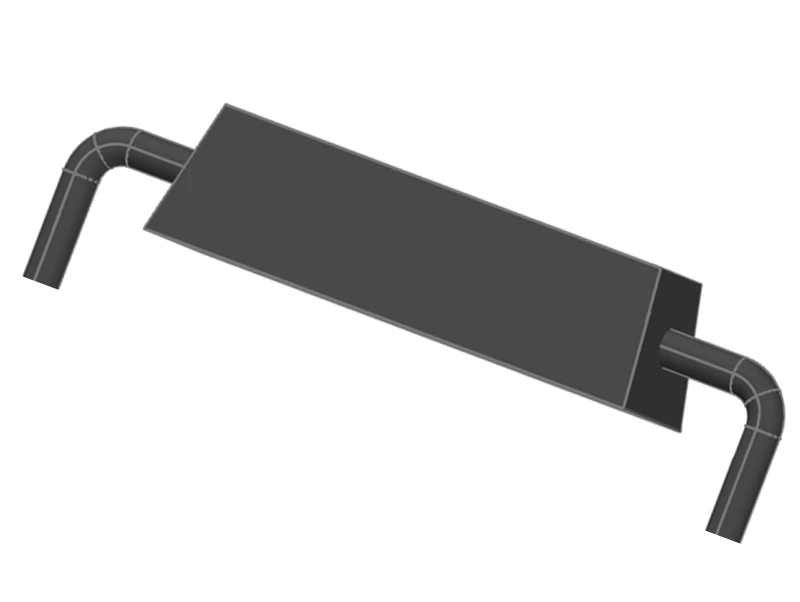

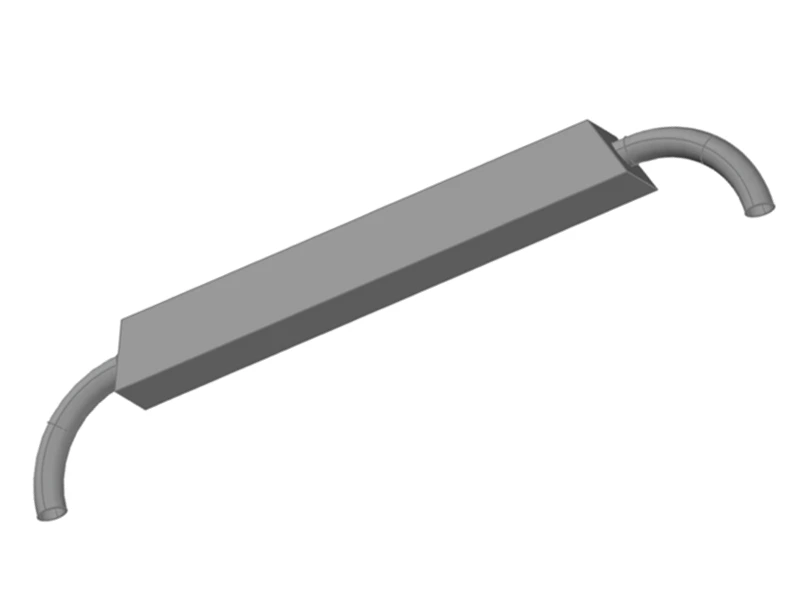

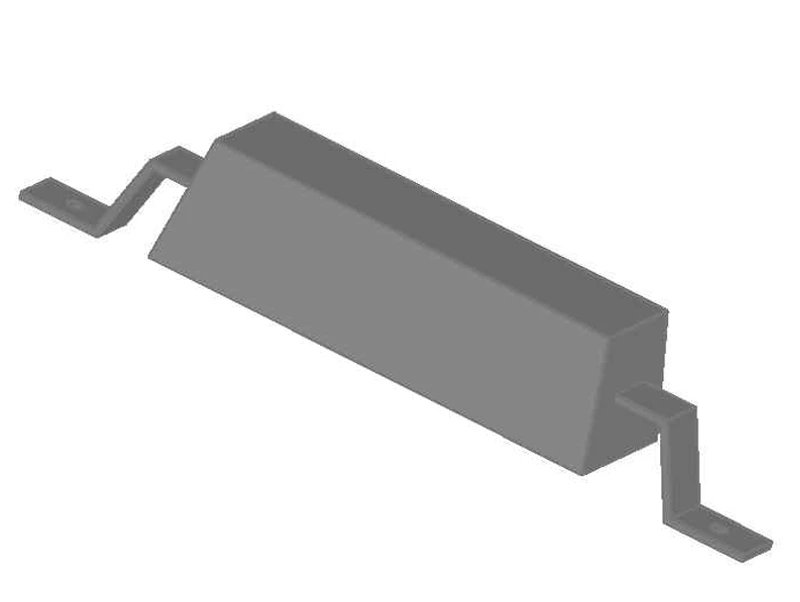

Aluminium Long Slender Anodes (ALSA) are aluminium slender anodes with a length of at least four times the radius (length ≥ 4 × radius). The anodes are used in a wide range of offshore, inshore, and internal tank applications.

Existing or new structures: underwater welding by certified divers.

Ideal for structures requiring flat profile anodes that do not protrude.

Specially designed for marine vessels, suitable for both newbuild and existing ships. Compliant with BKI Volume G guidelines.

Aluminium anodes must not be used in:

Reason: risk of thermite spark ignition → fire/explosion hazard.

Compliant with international marine safety and class regulations.

WhatsApp us